Energy. Evolved.

Magnets are at the heart of electrification. Our powerful, next-generation EcoFlux magnets are changing the way we electrify the world, ushering in a new era of mobility and high-efficiency, low-carbon energy production.

THE PROBLEM | 02/07

The uncertainties of an electric future.

Resource Pressure

The world’s population is expected to reach 9 billion by 2040, driving an ever-increasing demand for energy.

Foreign Dependency

The U.S. is >90% dependent on China for the production of rare earth magnets, causing price and supply chain volatility.

Limited Supply

The demand for rare earth magnets that power our future is expected to outpace supply by 2025.

Harmful Processes

Traditional manufacturing methods for rare earth magnets are toxic to humans and the environment and contribute to global warming.

OUR MISSION | 03/07

Developing a better magnet isn’t just our mission — it’s our responsibility.

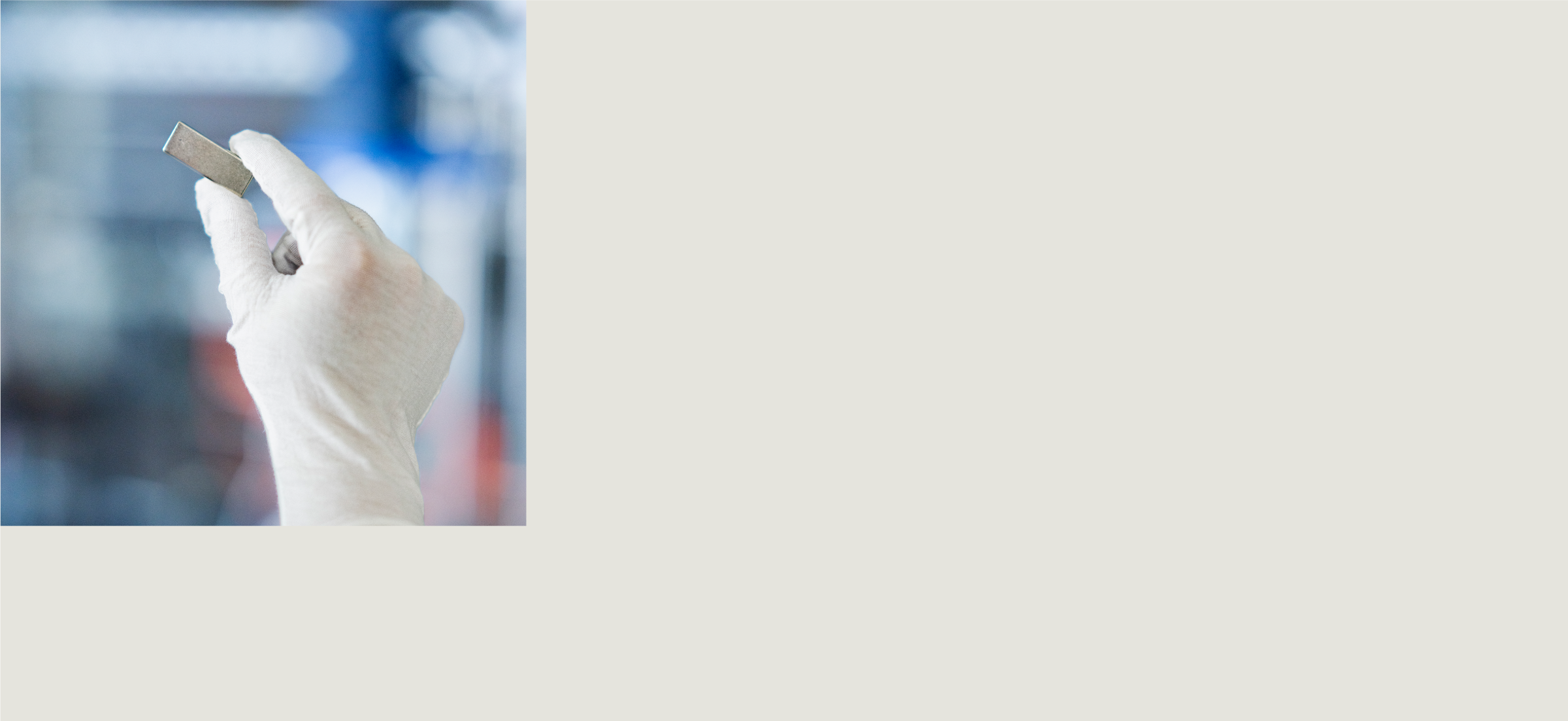

INTRODUCING ECOFLUX | 04/07

The state of the art.

Our first-of-its-kind technology enables us to create a superior magnet: EcoFlux. It displays the highest performance with the least amount of rare earth elements of any magnet while requiring less than 10% of the energy used in traditional mining and manufacturing.

OUR SOLUTION | 05/07

It starts with redefining the supply chain …

Our process is built around an abundant, alternative source of magnetic materials and the development of a decentralized supply chain. We can mitigate supply interruptions and subsequent price fluctuations using our advanced processes and technology. The result is a perfectly self-contained and closed-loop solution.

… and ends with the preservation of our planet.

Our patented products and processes leverage the potential for end-of-life recycling. They eliminate the most environmentally harmful aspects of rare earth mining and magnet manufacturing, achieving 90% energy savings compared to traditional methods and reducing environmental impact by 50%.

NEWS | 06/07

Get the latest from Noveon.

Stay up to date with a curated selection of industry news, current events and important announcements from Noveon.

CONTACT | 07/07

Let’s connect.

Contact us today to see how we can bring your rare earth magnet project to life.